ISO 9001 : 2015

CERTIFIED

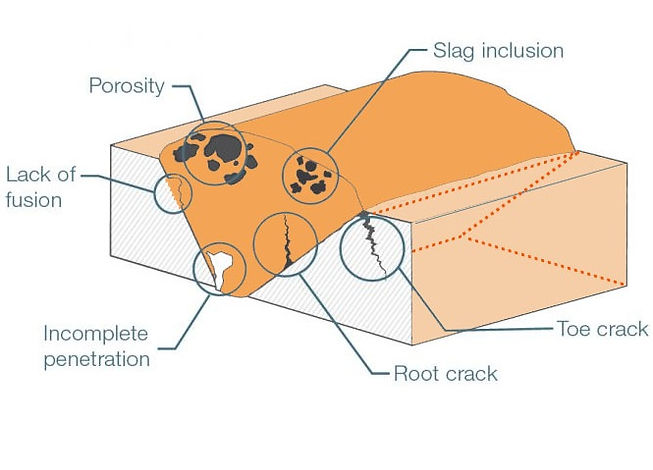

Weld inspection

AVN Technologies offer an efficient solution for weld joint surface inspection.

1.

Eddy Current

Detect surface and subsurface cracks quickly and efficiently

-

High probability of detection without paint removal

-

Save time with wide coverage and fast scanning

-

Replaces penetrant and magnetic particle testings

2.

Industrial Microscopy

Inspect the cross section of welds with our imaging solutions

-

Completes all measurements in a single step for fast inspections

-

Works for tee, lap, and corner joints and all weld sizes

-

Calibrated imaging for reliable results

3.

Conventional Ultrasound

High-quality flaw detection with exceptional ease of use

-

Rugged, ergonomic design enables use in challenging environments

-

Intuitive interface is practical for both experienced and novice inspectors

-

Full range of UT probes for detecting and sizing weld defects

4.

Remote Visual Inspection

Inspect hard-to-reach areas

-

The best image quality for clear visualization

-

Increase the probability of detection with vivid colors and sharp images

-

Efficiently assess welding damage

5.

Phased Array Ultrasound

Speed up your inspection process

-

High-speed detection capabilities facilitate interpretation

-

Reduced inspection time compared to radiography

-

Immediate results enable you to detect and fix process problems right away

6.

X-Ray Fluorescence

On-the-spot weld inspection and positive material identification

-

Alloy verification helps ensure proper weld materials are used

-

Avoid corrosion, cracks, and damage

-

Analysis in seconds with no impact to the weld